Open Mon- Sat 9:00 AM to 5:00 PM

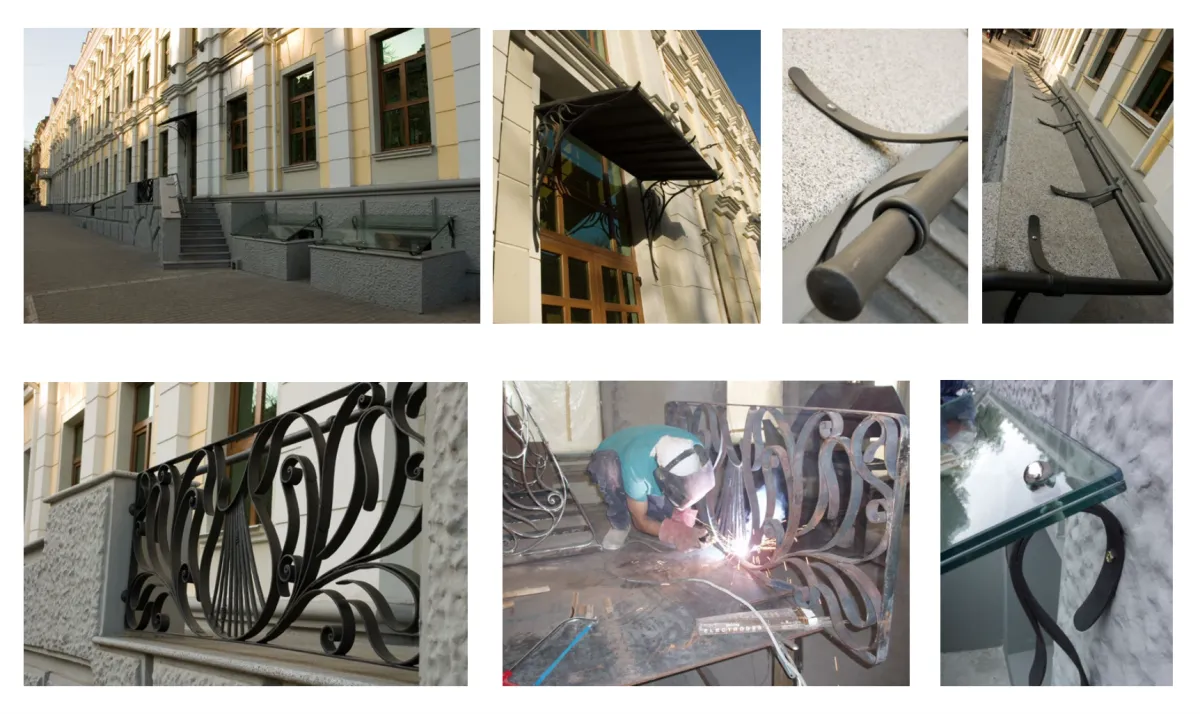

Expert Metal Fabrication Services in New York

Your trusted local partner for custom metalwork, structural steel fabrication, welding, and more. Serving New York and surrounding boroughs, we bring craftsmanship, precision, and reliability to every project — large or small.

ABOUT US

Quality, Experience, and Personal Service

At New York Metal Fabricator, we believe that quality, experience, and personal service make all the difference. Whether you're an architect needing intricate metal detailing or a homeowner looking for a custom railing, we have the expertise to bring your vision to life.

✅ Over 20 years of industry experience

✅ Full-service metal fabrication and welding

✅ Locally owned and operated in New York

✅ Fast turnarounds without compromising quality

✅ Competitive pricing and free estimates

We collaborate with a security system provide Empire Security Solutions

OUR FABRICATION SERVICES

We specialize in custom metal fabrication for residential, commercial, and industrial projects. Our team works with Steel, Brass, Bronze, Aluminum, Copper, and more to craft precision components, Furniture pieces, decorative elements, and Structural pieces, ensuring exceptional quality and attention to detail from start to finish.

And if you need a Sauna installer in Seattle, they are located here

Custom Metal Fabrication

We specialize in custom metal fabrication for residential, commercial, and industrial projects. Our team works with steel, aluminum, copper, and more to craft precision components, decorative elements, and structural pieces, ensuring exceptional quality and attention to detail from start to finish.

Metal Railings and Staircases

Custom metal railings and staircases combine safety, durability, and style. We design, fabricate, and install everything from sleek modern railings to Forged grand spiral staircases, using premium materials such as Wrought iron, Stainless Steel, and Bronze to fit your building’s needs and design goals.

Structural Steel Fabrication

We provide high-quality structural steel fabrication for buildings, renovations, and industrial facilities throughout New York. Our experienced team fabricates beams, columns, frames, and trusses with strict adherence to engineering standards, ensuring your project’s strength, safety, and long-term performance. Here is a Sauna Builder in Philadelphia

NYC-Compliant Commercial Outdoor Dining Structures

Since the City of New York legalized curbside outdoor dining in 2020, we’ve delivered dozens of premium outdoor dining structures for restaurants and bars throughout the five boroughs. Every project is built to meet NYC DOT compliance standards and carefully tailored to match each client’s functional needs and design vision. We work with a sauna builder in Tampa

Architectural Metalwork

Elevate your property’s design with custom architectural metalwork, including decorative facades, canopies, panels, and artistic installations. We work closely with architects, designers, and property owners to deliver stunning, durable pieces that enhance aesthetics while maintaining functionality and structural integrity.

Welding Services

Our certified welding services include MIG, TIG, and Stick welding for structural, industrial, and decorative projects. We offer both mobile and in-shop welding solutions, delivering strong, precise welds that meet code requirements and stand the test of time, no matter the application.

What Our Customers Are Saying

"New York Metal Fabricator delivered exactly what we envisioned — beautiful, strong custom railings. Professional, timely, and highly recommended!"

James T., Manhattan, NY

"Fantastic experience from start to finish. Their team was knowledgeable, responsive, and the quality of the metalwork exceeded expectations."

Emily R., Brooklyn, NY

"Our custom staircase turned out amazing. Great craftsmanship, attention to detail, and excellent communication throughout the entire project."

Daniel M., Queens, NY

MORE FROM OUR WORK

Restaurant Customization

Custom Furniture

Metal Fencing

Large Scale Staircases

Outdoor Structures

Art Commissions

Our Process

At New York Metal Fabricator, we believe that an exceptional product begins with an exceptional process. From the first conversation to the final delivery or installation, we ensure every step is clear, collaborative, and crafted with precision. Whether you’re commissioning a single custom piece or overseeing a large construction project, you can expect a smooth, transparent experience from start to finish. Searching for a custom sauna builder in Los Angeles? Start here. Also, Need professional siding installation in Kennesaw GA? Contact these guys.

Here’s what you can expect when you work with us:

Consultation & Design

We start by learning about your project goals, specifications, and timeline during a detailed consultation. Our team then develops precise drawings and, when needed, 3D models to bring your vision to life. Every design is reviewed closely with you before moving forward to ensure it meets your needs, budget, and expectations. Our goal is simple: full transparency, clear communication, and a design you love.

Fabrication

After final design approval, our skilled craftsmen get to work. We use premium metals and advanced fabrication techniques to cut, bend, weld, and finish each piece with precision. Every item is tailored to exact project specifications, whether for decorative metalwork or heavy structural steel. Combining traditional craftsmanship with the latest technology, we deliver exceptional, dependable products every time. The best Intercom and Security System Installer in New York City

Installation

If you choose, we also offer expert installation services. Our professional team installs structural steel, custom railings, staircases, and architectural pieces with precision and safety. We coordinate with other contractors or property managers to minimize disruptions and ensure compliance with building codes. Our focus is a perfect, secure fit that looks great and performs flawlessly for years to come.

Quality Assurance

Every project goes through a thorough quality inspection before it leaves our shop. We review all welds, dimensions, surface finishes, and strength to ensure the final product meets the highest standards. Any imperfections are corrected immediately. Our strict quality control ensures that you receive not just a finished product, but one that is flawless, durable, and made to last.

FAQ

What is metal fabrication?

Metal fabrication is all about turning raw metal—like sheets, bars, or tubes—into something useful or beautiful. Whether it's a staircase, a custom bracket, or part of a building's frame, the process typically involves cutting, bending, welding, and refining the material until it fits its purpose. It’s a craft that requires precision and hands-on skill, especially when working on detailed architectural elements or heavy-duty industrial parts. You’ll find fabrication at the core of countless industries—construction, transportation, even public art installations. It’s one of those behind-the-scenes trades that quietly shapes much of the world around us.

What types of metals are typically used in fabrication?

Fabricators work with a variety of metals depending on the application, performance requirements, and aesthetic preferences. Common metals include carbon steel, which offers strength and affordability for structural applications; stainless steel, valued for its corrosion resistance and sleek appearance; aluminum, which is lightweight yet strong and often used in architectural and transportation projects; and non-ferrous metals like brass and copper, which are prized for their beauty and are often used in custom fixtures and ornamental work. Each material behaves differently when it is cut, formed, or welded, so part of a fabricator’s expertise lies in knowing which material best suits a given project and how to properly work with it.

How to chose metal for my project?

Picking the right metal for a job isn’t always straightforward—it depends on a mix of things like strength, weather exposure, looks, and budget. If the piece is going outside, for instance, you’ll want something that holds up well against rust—stainless or galvanized steel usually do the trick. On the other hand, if keeping it lightweight matters, aluminum is often a smart go-to, especially for mobile or decorative elements. For projects where the finish really counts—like a feature staircase or a custom panel—brass or polished stainless can give that clean, high-end look. Each metal has its own pros and quirks, so knowing what to expect in terms of durability, upkeep, and style is key. That’s where an experienced fabricator really comes in handy—they can help you weigh the options and land on what works best.

How long does a fabrication project typically take?

How long a metal fabrication project takes really depends on a few key things—like how complex the job is, whether the materials are readily available, and how long it takes to get the design approved. For something simple, like a basic railing, you could be looking at just a few days to a week. But when it comes to bigger or more involved projects—say, a steel frame for a building—it might take several weeks or even months, especially if there are a lot of moving parts or last-minute design changes. On top of that, the timeline usually includes time for inspections, surface finishing, and sometimes installation. Staying in sync during the design phase makes a big difference and can help keep the whole process on track

What happens during the installation?

If your project requires installation, careful planning continues into this final phase. Installation involves transporting the finished metalwork to the site, ensuring it is properly supported during placement, and securely fastening it according to structural or design requirements. Larger projects may require cranes, rigging equipment, or welding on-site to assemble and install components safely. Installations must comply with building codes and safety standards to ensure long-term performance and occupant safety. Experienced installers take precise measurements on-site before installation begins to avoid costly adjustments later. They also work closely with other trades, such as architects, contractors, or electricians, when coordination is necessary for a successful project.

How is metal fabrication different from welding?

While metal fabrication and welding are closely related, they are not the same thing. Metal fabrication is the broader process that involves the entire creation of a metal product, from initial design through final assembly. It includes cutting raw materials to size, bending or shaping them, welding them together, and applying any finishes needed for protection or aesthetics. Welding is just one part of this larger process. Specifically, welding joins two pieces of metal by heating them to the point of fusion. In short, welding is a technique within the wider craft of fabrication, much like how baking is one part of cooking. A fabricator may weld as part of their work, but fabrication covers the full journey from raw material to finished product.

Is a permit required for outdoor dining in NYC?

Yes. The NYC DOT requires all outdoor dining setups to follow Open Restaurants Program rules. A permit or self-certification may be required depending on location and structure type.

What materials are allowed?

Metal framing (steel or aluminum) is preferred. Plywood structures are being phased out. Roofs must handle snow load and provide drainage.

Can I brand my outdoor structure?

Yes. We offer custom signage, color-matching, vinyl wraps, and laser-cut logo panels.

What happens if the rules change?

Our team monitors DOT updates. We offer compliance checkups and modifications if your structure needs to be updated.

What are the most common fabrication techniques?

Metal fabrication uses a bunch of different techniques, each one suited to a specific part of the job. It usually starts with cutting—using tools like shears, plasma cutters, or lasers to get the metal into the right shape and size. After that comes bending or forming, where presses or rollers are used to create curves, angles, or folds. Then there’s welding, which joins everything together. TIG welding is great for precise, cleaner joints, while MIG welding works well for bigger, structural pieces. Once everything's assembled, finishing steps like grinding, sanding, polishing, or coating come into play to protect the surface and give it a clean, polished look. Every step takes the right tools and know-how, and fabricators have to choose the best mix of techniques to make sure the job gets done right.

Why is finishing important in metal fabrication?

Finishing is a critical part of metal fabrication that is sometimes overlooked. It not only affects the appearance of the final product but also its durability and performance. A raw metal surface is vulnerable to corrosion, scratches, and other forms of damage. Finishes like powder coating, galvanizing, anodizing, or polishing provide layers of protection and extend the lifespan of the metal, especially in outdoor or high-traffic environments. Finishing also enhances visual appeal, whether you want a sleek, modern look with polished stainless steel or a more industrial style with a matte finish. Choosing the right finish is just as important as selecting the right metal, and it should be considered early in the design process.

How do fabricators ensure quality and accuracy?

Keeping things accurate in metal fabrication takes focus and consistency every step of the way. It all starts with getting the design right—clear, precise drawings lay the groundwork. From there, everything from cutting and bending to welding and finishing has to follow suit. Fabricators rely on tools like calipers, laser guides, and weld gauges to make sure every measurement stays on point. Even before the work begins, the materials get a once-over to check for any flaws. And throughout the process, each weld and joint is double-checked to make sure it’s solid and clean. A good fabricator knows that spotting a mistake early on saves a lot of trouble later—especially compared to finding it after everything’s been installed. Brooklyn’s go-to security installer – find them here

© Copyright 2026 New York Metal Fabricator. All Rights Reserved.